Melamine Board

We have our own professional and perfect team of designers, who update the surface design of different effects and colors every month, including wood grain, stone grain, solid color, marble grain, leather grain and so on. We have the most cutting-edge design inspiration and concept, and have different styles of targeted color schemes for different markets, which can meet the aesthetic needs of different markets and customers. We Can provide customers with timely and effective product solutions, and can also be designed and customized according to customer requirements.

OTHER SERVICES

Pintree’s all products

LET’S WORK TOGETHER!

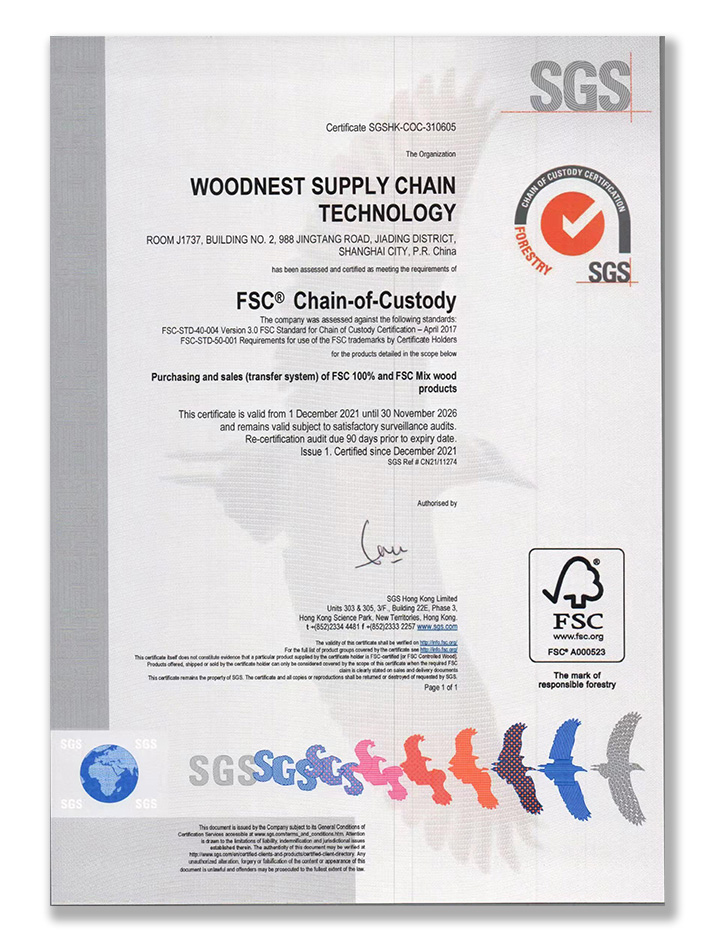

Our Certification

Inspiro is the perfect solution to create a beautiful website for your portfolio or your business. If you’re looking to create a captivating presence online, then you’ve found the right tool. The theme is easy to manage, with a drag-and-drop interface and fully customizable using the Theme Customizer.

Why us?

PinTree Group,.Ltd was established in 1994 and has been engaged in the plywood board industry for 30 years. We always focuses on mealmine board,uv board,fancy plywood,melamine paper design,pet panel,slatwall panel,wood veneer and customized furniture etc, we also an comprehensive group company with R&D, design, production, sales and integrating whole services.

Our company owned 35 subsidiaries& 1,300 warehouse distribution service outlets.

We have 2 plywood production bases with an annual production capacity of 100,000CBM, and 3 particle board production bases with 600,000cbm annual production capacity ,also owned particle board and melamine production lines.

Our Team

Maggie chen

Jalon Song

Nancy An

Exhibition show

How to contact us

Get a inquiry

Address 1:10th floor, Guyi Business Building, no.

4929 zhennan Road, Jiading

District, Shanghai

Address 2:Pinganshu Group, Yitang

Industrial Park, Lanshan

District, Linyi city, Shandong

Address 3:No.67.Nanhuan Road, Mohekou

Industrial Park, Huaishang

District, Bengbu city, Anhui

Email :[email protected]

Phone :+86 15000357176

Let’s connect!

Contact Us

Catalogue

What we do

Mail

Youtube

Facebook