what is film faced plywood waterproof ?

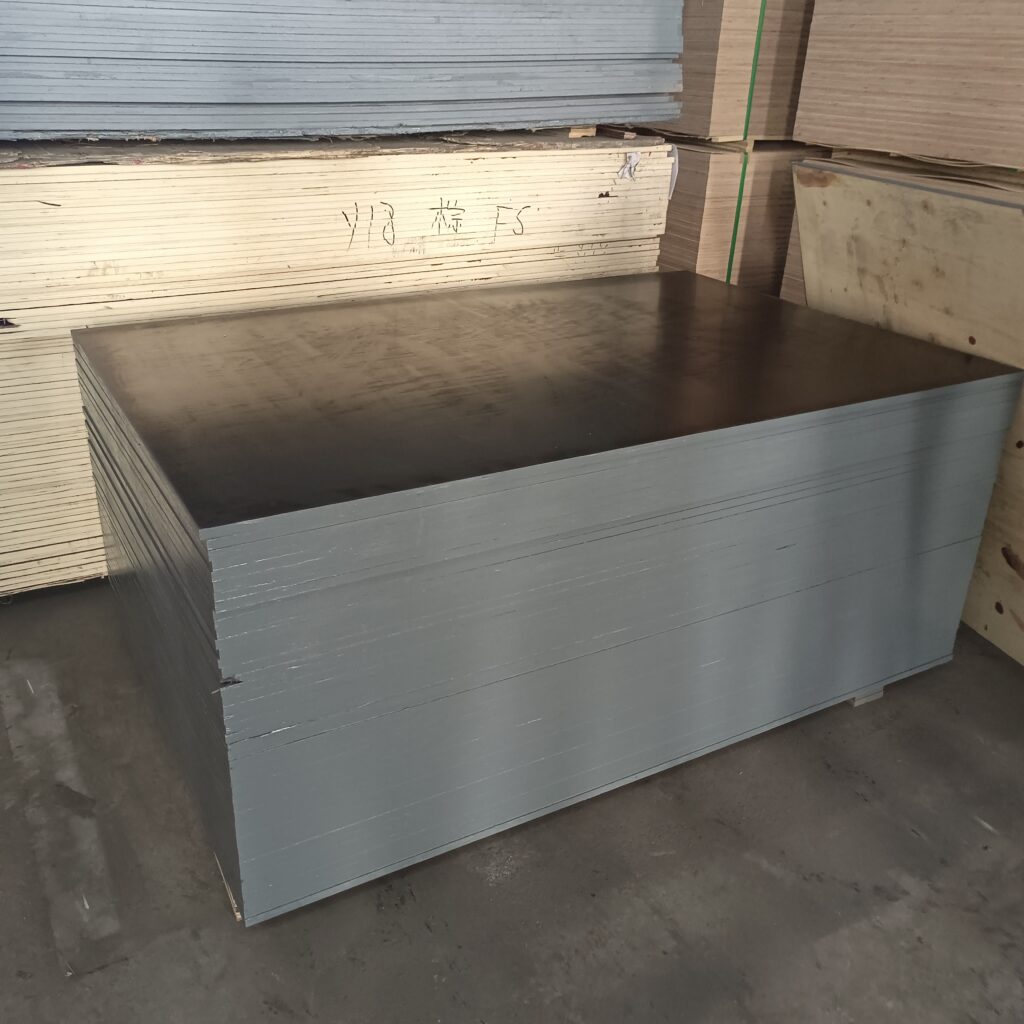

what is film faced plywood waterproof ? Film faced plywood waterproof, also known as shuttering plywood or formwork plywood, is a type of plywood that is specifically designed for use in construction and formwork applications. It is characterized by a durable and smooth film coating on one or both sides of the plywood panels. The film used in film-faced plywood is typically made from phenolic resin or melamine-urea-formaldehyde, which provides excellent resistance to moisture, chemicals, and mechanical stress.

The film coating serves several important purposes in film faced plywood waterproof:

- Protection: The film acts as a protective layer, shielding the plywood core from moisture, humidity, and other environmental factors. It helps to prevent the plywood from warping, swelling, or delaminating when exposed to water or moisture.

- Smooth Surface: The film coating creates a smooth and even surface on the plywood, which is essential for achieving high-quality finishes in concrete formwork applications. The smooth surface allows for easy release of the formwork and helps to produce a clean and uniform concrete surface.

- Easy Cleaning: film faced plywood waterproof is easy to clean due to its smooth and non-porous surface. Any spills, dirt, or concrete residue can be easily wiped off, making it suitable for multiple uses and reducing maintenance efforts.

- Improved Durability: The film coating enhances the overall durability and strength of the plywood. It provides protection against scratches, abrasion, and impact, extending the lifespan of the plywood and making it suitable for rugged construction environments.

Film faced plywood waterproof offers several advantages and benefits:

- Moisture Resistance: The film coating on film faced plywood provides superior moisture resistance compared to regular plywood. This makes it suitable for applications where exposure to water or high humidity is expected, such as concrete formwork, exterior construction, and marine applications.

- Chemical Resistance: The film coating on film-faced plywood offers excellent resistance to chemicals, including alkaline substances present in concrete. This ensures that the plywood remains structurally intact and unaffected by chemical reactions during formwork applications.

- Easy Handling and Installation: film faced plywood waterproof is lightweight and easy to handle, allowing for quick and efficient installation. It can be easily cut, shaped, and fastened using standard woodworking tools and techniques.

- Versatility: film faced plywood waterproof is highly versatile and finds applications in various construction projects. It is commonly used in concrete formwork, including walls, slabs, columns, and beams. It is also utilized for exterior cladding, flooring, hoardings, and packaging.

In summary, film faced plywood waterproof is a specialized type of plywood that features a durable and smooth film coating on one or both sides. It offers excellent moisture and chemical resistance, a smooth surface for formwork applications, easy cleaning, improved durability, and versatility. Its key advantages make it a preferred choice in construction projects where durability, moisture resistance, and high-quality finishes are required.