Film faced plywood vs marine plywood

Film faced plywood and marine plywood are two distinct types of plywood that serve different purposes and have unique characteristics. While both are commonly used in construction and other applications, they differ in terms of composition, construction, performance, and recommended uses. Let’s explore the differences between film faced plywood vs marine plywood in detail.

Composition:

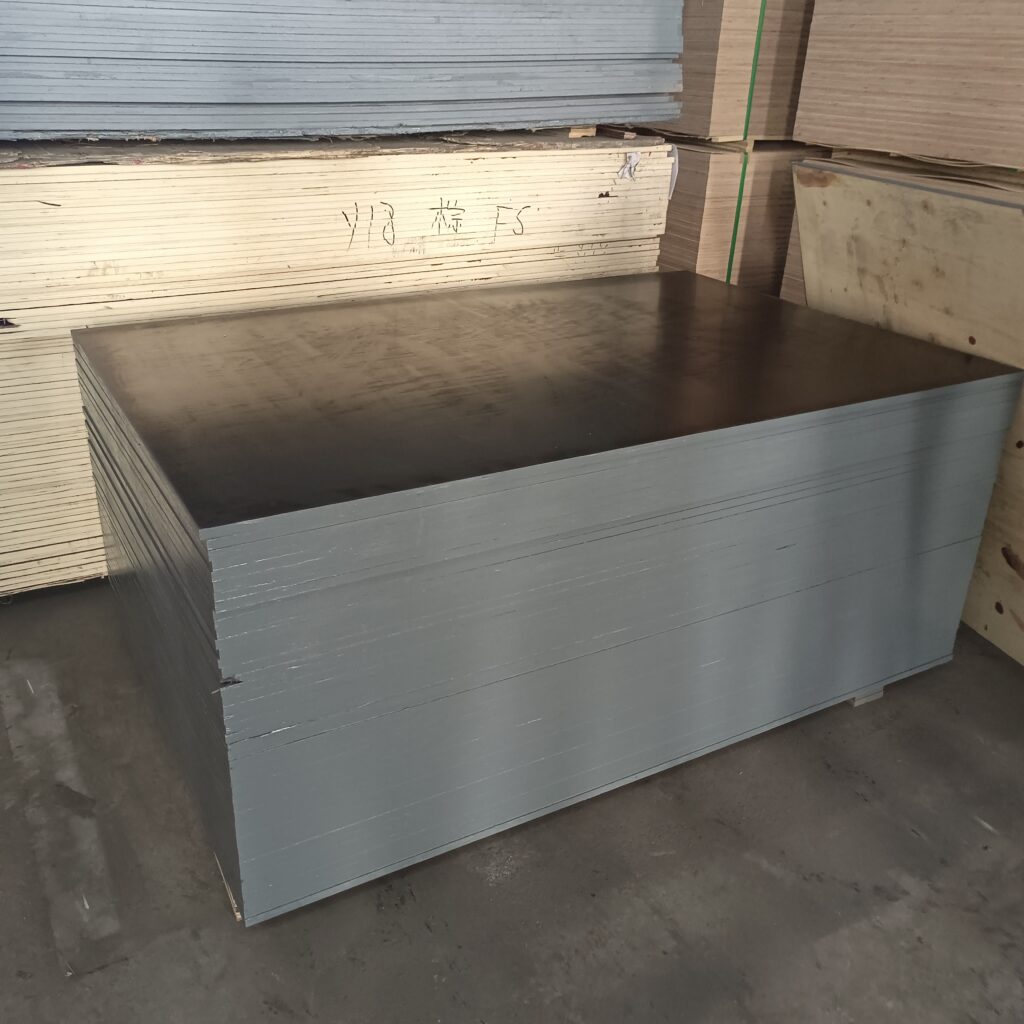

Film-faced Plywood: Film faced plywood consists of multiple layers or plies of wood veneers that are bonded together with an adhesive. The plies are typically made from hardwood or softwood, depending on the intended application. The distinguishing feature of film faced plywood is the presence of a durable film coating, usually made from phenolic resin or melamine, on one or both sides of the plywood panels.

Marine Plywood: Marine plywood is also composed of several layers of wood veneers, bonded together with an adhesive. However, marine plywood is constructed using high-quality hardwood veneers throughout its entire structure. It is specifically designed to have superior moisture resistance and durability compared to standard plywood. Marine plywood is typically manufactured using phenolic or melamine adhesives.

Film faced plywood vs marine plywood Moisture Resistance:

Film faced Plywood: Film faced plywood offers moderate moisture resistance due to the presence of the film coating. The film acts as a barrier, protecting the plywood core from moisture and preventing warping, swelling, or delamination. However, the level of moisture resistance can vary depending on the quality of the film coating and the specific application.

Marine Plywood: Marine plywood is specifically engineered to have excellent moisture resistance. It is designed to withstand prolonged exposure to water and high humidity without significant structural damage. Marine plywood achieves this high level of moisture resistance through the use of high-quality hardwood veneers and superior adhesive formulations.

Durability:

Film faced Plywood: Film faced plywood is relatively durable, thanks to the film coating that provides added protection against scratches, abrasion, and impact. The film helps maintain the structural integrity of the plywood and extends its lifespan. However, the durability of film-faced plywood may vary depending on the thickness and quality of the film coating.

Marine Plywood: Marine plywood is renowned for its exceptional durability. It is built to withstand harsh conditions, including exposure to water, moisture, and weather elements. Marine plywood’s high-quality hardwood veneers and superior adhesive bonding make it highly resistant to warping, rotting, and delamination, ensuring long-term structural integrity.

Recommended Uses:

Film faced Plywood: Film faced plywood is primarily used in construction, particularly in concrete formwork applications. The smooth and durable film coating provides a consistent surface finish and facilitates the easy release of the formwork after concrete pouring. Film-faced plywood is also used in exterior cladding, hoardings, packaging, and various applications that require moisture resistance and a smooth surface.

Marine Plywood: Marine plywood is widely used in applications that demand superior moisture resistance and durability. Its main application is in boat building and marine environments, where it is used for hulls, decks, bulkheads, and other structural components. Marine plywood is also suitable for exterior construction, including roofing, flooring, and walls, where moisture resistance and long-lasting performance are essential.

Cost Considerations:

Film-faced Plywood: Film faced plywood is generally more affordable compared to marine plywood. Its lower cost can make it a preferred choice for construction projects where moderate moisture resistance is required, and budget constraints are a consideration.

Marine Plywood: Marine plywood is typically more expensive compared to film faced plywood due to the higher quality of materials used and the specialized manufacturing processes involved. The enhanced moisture resistance and durability of marine plywood justify the higher cost, particularly for applications in wet or marine environments.

In summary, film faced plywood and marine plywood have distinct differences in their composition, moisture resistance, durability, recommended uses, and cost. Film faced plywood is characterized by a film coating that provides moderate moisture resistance and durability, making it suitable for construction and formwork applications. Marine plywood, on the other hand, is constructed using high-quality hardwood veneers and superior adhesives, offering excellent moisture resistance and exceptional durability. It is commonly used in boat building, marine applications, and exterior construction projects. Understanding these differences helps in selecting the appropriate plywood type for specific applications based on the required level of moisture resistance, durability, and budget considerations.