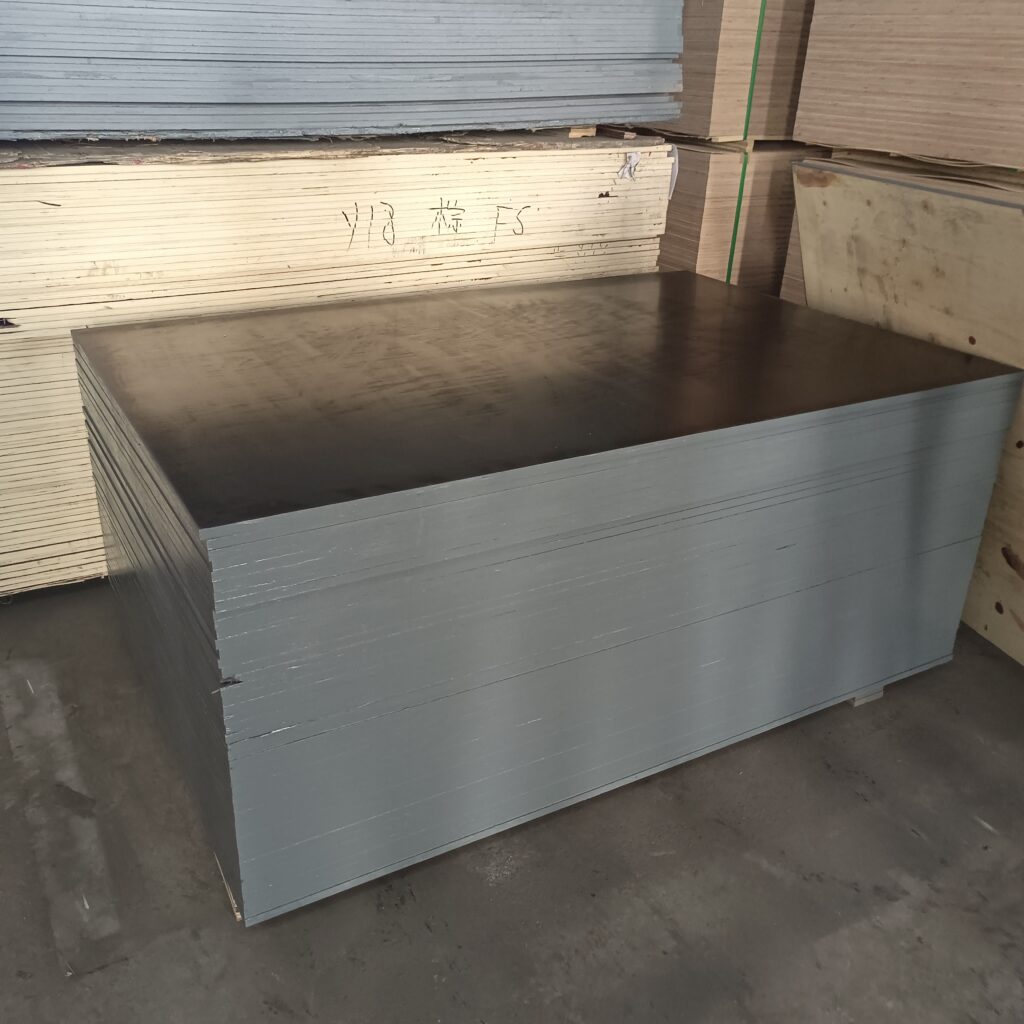

18mm Film Faced Plywood 2440 x 1220 Phenolic Film Faced Ply – Smooth

18mm Film Faced Plywood 2440 x 1220 Phenolic Film Faced Ply – Smooth

18mm film faced plywood possesses several notable features that contribute to its popularity and practicality

- High Strength: The 18mm thickness of film faced plywood provides excellent structural strength and stability, making it suitable for heavy-duty applications.

- Film Coating: The plywood is coated with a phenolic film on one or both sides, offering enhanced durability, moisture resistance, and a smooth surface finish.

- Moisture Resistance: The phenolic film acts as a protective barrier, preventing moisture absorption and protecting the plywood from warping, swelling, and delamination.

- Chemical Resistance: 18mm film faced plywood exhibits resistance to various chemicals, including alkaline substances present in concrete, ensuring its longevity and performance in demanding environments.

- Easy Handling: Despite its thickness, 18mm film faced plywood remains relatively lightweight, making it easy to handle, transport, and install.

Advantages of 18mm Film Faced Plywood:

The use of 18mm film faced plywood offers several advantages in construction and other industries:

- Durability and Longevity: The film coating enhances the plywood’s resistance to wear, impact, and abrasion, resulting in increased durability and a longer lifespan.

- Moisture Resistance: The plywood’s moisture resistance makes it ideal for applications in humid or wet environments, such as concrete formwork, where protection against water damage is crucial.

- Smooth Surface Finish: The smooth surface of film faced plywood eliminates the need for additional surface treatments. It provides a high-quality finish in concrete formwork and other applications, saving time and labor costs.

- Versatile Applications: 18mm film faced plywood finds diverse applications in construction, including concrete formwork, exterior cladding, flooring, packaging, and more. Its strength, moisture resistance, and chemical resistance make it suitable for various demanding scenarios.

- Cost-Effectiveness: Film faced plywood offers a cost-effective solution compared to other materials. Its durability reduces maintenance and replacement costs over time, providing long-term savings.

Usage Scenarios of 18mm Film Faced Plywood:

- Concrete Formwork: The smooth surface and moisture resistance of 18mm film faced plywood make it ideal for concrete formwork applications. It provides a stable and high-quality finish on the formed surface, ensuring excellent concrete results.

- Exterior Cladding: The durability and weather resistance of film faced plywood make it suitable for exterior cladding projects. Its moisture resistance protects against the elements, while the smooth surface allows for easy installation and an appealing aesthetic.

- Flooring: 18mm film faced plywood can be used as a subfloor or underlayment material. Its strength and moisture resistance make it a reliable choice for flooring applications, providing a stable and durable foundation.

- Packaging: The robustness of film faced plywood makes it suitable for packaging applications that require strength, protection, and moisture resistance. It can be used for crates, pallets, and containers to ensure secure and safe transportation of goods.

- Industrial Applications: Film faced plywood finds usage in various industrial settings, such as manufacturing, warehouse construction, and industrial shelving. Its strength and durability make it an ideal choice for supporting heavy loads and ensuring structural stability.

Summary:

18mm film faced plywood is a versatile building material with numerous features and advantages. Its high strength, moisture resistance, smooth surface finish, and chemical resistance make it suitable for a wide range of applications. From concrete formwork to exterior cladding, flooring, packaging, and industrial uses, film faced plywood offers durability, longevity, and cost-effectiveness. Its easy handling and installation further contribute to its popularity in the construction industry. By choosing 18mm film faced plywood, builders and manufacturers can benefit from a reliable, moisture-resistant, and versatile material that meets the demands of various projects.